Page 9 - Open-Access-May-2020

P. 9

TECHNICAL PAPER

(c) (d)

(a) (b) (e)

(g) (f)

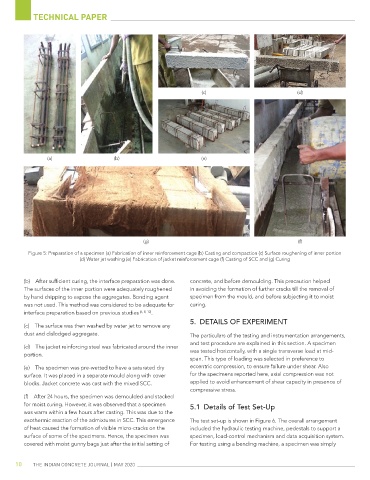

Figure 5: Preparation of a specimen (a) Fabrication of inner reinforcement cage (b) Casting and compaction (c) Surface roughening of inner portion

(d) Water jet washing (e) Fabrication of jacket reinforcement cage (f) Casting of SCC and (g) Curing

(b) After sufficient curing, the interface preparation was done. concrete, and before demoulding. This precaution helped

The surfaces of the inner portion were adequately roughened in avoiding the formation of further cracks till the removal of

by hand chipping to expose the aggregates. Bonding agent specimen from the mould, and before subjecting it to moist

was not used. This method was considered to be adequate for curing.

interface preparation based on previous studies [6, 8, 12] .

5. DETAILS OF EXPERIMENT

(c) The surface was then washed by water jet to remove any

dust and dislodged aggregate. The particulars of the testing and instrumentation arrangements,

and test procedure are explained in this section. A specimen

(d) The jacket reinforcing steel was fabricated around the inner

portion. was tested horizontally, with a single transverse load at mid-

span. This type of loading was selected in preference to

(e) The specimen was pre-wetted to have a saturated dry eccentric compression, to ensure failure under shear. Also

surface. It was placed in a separate mould along with cover for the specimens reported here, axial compression was not

blocks. jacket concrete was cast with the mixed SCC. applied to avoid enhancement of shear capacity in presence of

compressive stress.

(f) After 24 hours, the specimen was demoulded and stacked

for moist curing. However, it was observed that a specimen 5.1 Details of Test Set-Up

was warm within a few hours after casting. This was due to the

exothermic reaction of the admixtures in SCC. This emergence The test set-up is shown in Figure 6. The overall arrangement

of heat caused the formation of visible micro-cracks on the included the hydraulic testing machine, pedestals to support a

surface of some of the specimens. Hence, the specimen was specimen, load-control mechanism and data acquisition system.

covered with moist gunny bags just after the initial setting of For testing using a bending machine, a specimen was simply

10 The IndIan ConCreTe Journal | MaY 2020