Page 7 - Open-Access-May-2020

P. 7

TECHNICAL PAPER

at the compressive strengths of inner and jacket concrete. corresponding to HSSCC and NSSCC with target strengths of

th

Inner portion concrete had a 30-day gap between 28 day and 70 MPa and 40 MPa respectively, were adopted from a previous

test day. The specimens were tested on 28 days age of jacket study [17] . The flowability through the narrow space in the

concrete. formwork without segregation or bleeding is necessary during

jacketing. The self-compactibility was achieved by limiting the

4.2.1 Conventional Concrete for the Inner coarse aggregate content (which reduced the internal stresses

Portion due to aggregate particle friction) and using superplasticizer.

The SCC was mixed in a pan-type tilting mixer machine, poured

The inner portion concrete consisted of ordinary portland in a mould and allowed to set without any compaction (Figure 3).

cement, fine aggregate (river sand), coarse aggregate of

nominal size 20 mm and water as the constituents. Mineral

or chemical admixtures were not added. The concrete was

prepared in a conventional drum-type mixer machine of 100

litres capacity. It was placed in a mould and compacted using

a needle vibrator. The target strength of the inner portions of

jacketed specimens was 20 MPa. This was similar to that used in

existing buildings.

4.2.2 SCC for the Jacket Portion

The SCC had portland pozzolana cement, fine aggregate (river

sand), coarse aggregate of nominal size 8 mm, superplasticizer

and water as its constituents. The superplasticizer was poly-

carboxylic ether based, with low viscosity and high performance (a) (b)

quality. In the trial mixes, these constituents were adjusted such Figure 3: Preparation of SCC (a) Mixing of ingredients and

that the concrete flowed under its own weight. The mix ratios (b) Casting of cubes

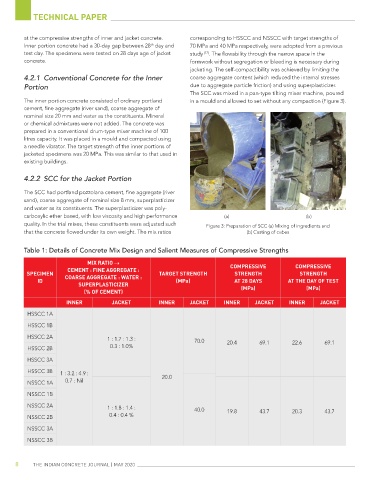

Table 1: Details of Concrete Mix Design and Salient Measures of Compressive Strengths

mix ratio →

cement : fine aggregate : comPreSSive comPreSSive

SPecimen coarSe aggregate : Water : target StrengtH StrengtH StrengtH

iD (mPa) at 28 DayS at tHe Day of teSt

SuPerPlaSticizer (mPa) (mPa)

(% of cement)

inner Jacket inner Jacket inner Jacket inner Jacket

HSSCC 1A

HSSCC 1B

HSSCC 2A 1 : 1.7 : 1.3 : 70.0

HSSCC 2B 0.3 : 1.0% 20.4 69.1 22.6 69.1

HSSCC 3A

HSSCC 3B 1 : 3.2 : 4.9 :

NSSCC 1A 0.7 : Nil 20.0

NSSCC 1B

NSSCC 2A 1 : 1.8 : 1.4 : 40.0 19.8 43.7 20.3 43.7

NSSCC 2B 0.4 : 0.4 %

NSSCC 3A

NSSCC 3B

8 The IndIan ConCreTe Journal | MaY 2020