Page 6 - June-2022

P. 6

TECHNICAL PAPER

having the specified yield strength of 500 MPa. All reinforcement All three selected grades of steel were adopted as the 2-legged

bars are made up of thermo-mechanically treated (TMT) steel transverse reinforcement of 10 mm diameter bars in both sets.

having a tough outer core and a soft inner core. These TMT Since the test specimens were designed to fail in shear, the

bars have higher tensile strengths and better elongation (or spacing of transverse reinforcements in beams was determined

ductility) and hence, are also suitable for seismic applications. from the shear force demand computed based on their

Two different concrete grades (i.e., M50 and M35) having the expected flexural capacities. The design shear strengths of

characteristics cube compressive strengths of 50 MPa and specimens were determined following IS: 456 (2000) provisions

[2]

35 MPa were adopted in the casting of test specimens. and were kept constant for all test specimens in a particular

set. The spacing of stirrups was varied in the test specimens to

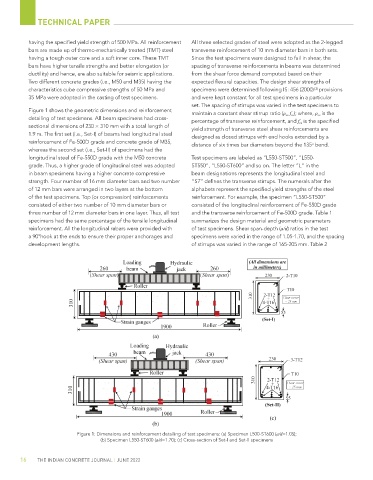

Figure 1 shows the geometric dimensions and reinforcement maintain a constant shear stirrup ratio (ρ sv f sv ); where, ρ sv is the

detailing of test specimens. All beam specimens had cross- percentage of transverse reinforcement, and f sv is the specified

sectional dimensions of 230 × 310 mm with a total length of yield strength of transverse steel . shear reinforcements are

1.9 m. The first set (i.e., Set-I) of beams had longitudinal steel designed as closed stirrups with end hooks extended by a

reinforcement of Fe-500D grade and concrete grade of M35, distance of six times bar diameters beyond the 135 bend.

o

whereas the second set (i.e., Set-II) of specimens had the

longitudinal steel of Fe-550D grade with the M50 concrete Test specimens are labeled as “L550-ST500”, “L550-

grade. Thus, a higher grade of longitudinal steel was adopted ST550”, “L550-ST600” and so on. The letter “L” in the

in beam specimens having a higher concrete compressive beam designations represents the longitudinal steel and

strength. Four number of 16 mm diameter bars and two number “ST” defines the transverse stirrups. The numerals after the

of 12 mm bars were arranged in two layers at the bottom alphabets represent the specified yield strengths of the steel

of the test specimens. Top (or compression) reinforcements reinforcement. For example, the specimen “L550-ST500”

consisted of either two number of 10 mm diameter bars or consisted of the longitudinal reinforcement of Fe-550D grade

three number of 12 mm diameter bars in one layer. Thus, all test and the transverse reinforcement of Fe-500D grade. Table 1

specimens had the same percentage of the tensile longitudinal summarizes the design material and geometric parameters

reinforcement. All the longitudinal rebars were provided with of test specimens. Shear span-depth (a/d) ratios in the test

a 90°hook at the ends to ensure their proper anchorages and specimens were varied in the range of 1.05-1.70, and the spacing

development lengths. of stirrups was varied in the range of 165-205 mm. Table 2

Figure 1: Dimensions and reinforcement detailing of test specimens: (a) Specimen L500-ST600 (a/d=1.05);

(b) Specimen L550-ST600 (a/d=1.70); (c) Cross-section of Set-I and Set-II specimens

16 THE INDIAN CONCRETE JOURNAL | JUNE 2022