Page 9 - March-2022

P. 9

TECHNICAL PAPER

Mortar matrix

Steel fibre

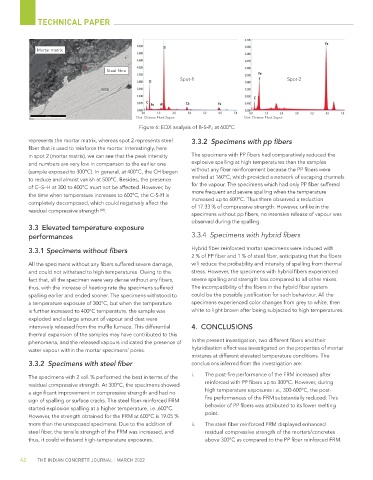

Spot-1 Spot-2

Det: Octane Elect Super Det: Octane Elect Super

Figure 6: EDX analysis of B-S-P S at 600°C

represents the mortar matrix, whereas spot 2 represents steel 3.3.2 Specimens with pp fibers

fiber that is used to reinforce the mortar. Interestingly, here

in spot 2 (mortar matrix), we can see that the peak intensity The specimens with PP fibers had comparatively reduced the

and numbers are very low in comparison to the earlier one explosive spalling at high temperatures than the samples

(sample exposed to 300°C). In general, at 400°C, the CH began without any fiber reinforcement because the PP fibers were

to reduce and almost vanish at 500°C. Besides, the presence melted at 160°C, which provided a network of escaping channels

of C–S–H at 300 to 400°C must not be affected. However, by for the vapour. The specimens which had only PP fiber suffered

the time when temperature increases to 600°C, the C-S-H is more frequent and severe spalling when the temperature

increased up to 600°C. Thus there observed a reduction

completely decomposed, which could negatively affect the of 17.33 % of compressive strength. However, unlike in the

residual compressive strength [18] .

specimens without pp fibers, no intensive release of vapour was

observed during the spalling.

3.3 Elevated temperature exposure

performances 3.3.4 Specimens with hybrid fibers

3.3.1 Specimens without fibers Hybrid fiber reinforced mortar specimens were induced with

2 % of PP fiber and 1 % of steel fiber, anticipating that the fibers

All the specimens without any fibers suffered severe damage, will reduce the probability and intensity of spalling from thermal

and could not withstand to high temperatures. Owing to the stress. However, the specimens with hybrid fibers experienced

fact that, all the specimen were very dense without any fibers, severe spalling and strength loss compared to all other mixes.

thus, with the increase of heating rate the specimens suffered The incompatibility of the fibers in the hybrid fiber system

spalling earlier and ended sooner. The specimens withstood to could be the possible justification for such behaviour. All the

a temperature exposure of 300°C, but when the temperature specimens experienced color changes from grey to white, then

is further increased to 400°C temperature, the sample was white to light brown after being subjected to high temperatures.

exploded and a large amount of vapour and dust were

intensively released from the muffle furnace. This differential 4. CONCLUSIONS

thermal expansion of the samples may have contributed to this

phenomena, and the released vapours indicated the presence of In the present investigation, two different fibers and their

water vapour within the mortar specimens’ pores. hybridisation effect was investigated on the properties of mortar

mixtures at different elevated temperature conditions. The

3.3.2 Specimens with steel fiber conclusions inferred from the investigation are:

The specimens with 2 vol. % performed the best in terms of the i. The post-fire performance of the FRM increased after

residual compressive strength. At 300°C, the specimens showed reinforced with PP fibers up to 300°C. However, during

a significant improvement in compressive strength and had no high temperature exposures i.e., 300-600°C, the post-

sign of spalling or surface cracks. The steel fiber-reinforced FRM fire performances of the FRM substantially reduced. This

started explosion spalling at a higher temperature, i.e.,600°C. behavior of PP fibers was attributed to its lower melting

However, the strength obtained for the FRM at 600°C is 19.05 % point.

more than the unexposed specimens. Due to the addition of ii. The steel fiber reinforced FRM displayed enhanced

steel fiber, the tensile strength of the FRM was increased, and residual compressive strength of the mortars/concretes

thus, it could withstand high-temperature exposures. above 300°C as compared to the PP fiber reinforced FRM.

42 THE INDIAN CONCRETE JOURNAL | MARCH 2022