Page 8 - March-2022

P. 8

TECHNICAL PAPER

Mortar matrix

ITZ

Steel fibre

EHT = 20.00 kV Signal A = HDBSD Date: 6 Apr 2022

WD = 9.37 mm Mag = 6.00 K X Time: 15:11:31

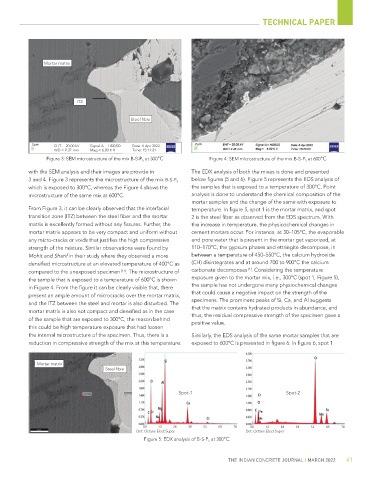

Figure 3: SEM microstructure of the mix B-S-P S at 300°C Figure 4: SEM microstructure of the mix B-S-P S at 600°C

with the SEM analysis and their images are provide in The EDX analysis of both the mixes is done and presented

3 and 4. Figure 3 represents the microstructure of the mix B-S-P S below figures (5 and 6). Figure 5 represents the EDS analysis of

which is exposed to 300°C, whereas the Figure 4 shows the the samples that is exposed to a temperature of 300°C. Point

microstructure of the same mix at 600°C. analysis is done to understand the chemical composition of the

mortar samples and the change of the same with exposure to

From Figure 3, it can be clearly observed that the interfacial temperature. In figure 5, spot 1 is the mortar matrix, and spot

transition zone (ITZ) between the steel fiber and the mortar 2 is the steel fiber as observed from the EDS spectrum. With

matrix is excellently formed without any fissures. Further, the the increase in temperature, the physicochemical changes in

mortar matrix appears to be very compact and uniform without cement mortars occur. For instance, at 30–105°C, the evaporable

any micro-cracks or voids that justifies the high compressive and pore water that is present in the mortar get vaporized, at

strength of the mixture. Similar observations were found by 110–170°C, the gypsum phases and ettringite decompose, in

Mohit and Sharif in their study where they observed a more between a temperature of 450–550°C, the calcium hydroxide

densified microstructure at an elevated temperature of 400°C as (CH) disintegrates and at around 700 to 900°C the calcium

[1]

compared to the unexposed specimen [17] . The microstructure of carbonate decomposes . Considering the temperature

the sample that is exposed to a temperature of 600°C is shown exposure given to the mortar mix, i.e., 300°C (spot 1, Figure 5),

in Figure 4. From the figure it can be clearly visible that, there the sample has not undergone many physiochemical changes

present an ample amount of microcracks over the mortar matrix, that could cause a negative impact on the strength of the

and the ITZ between the steel and mortar is also disturbed. The specimens. The prominent peaks of Si, Ca, and Al suggests

mortar matrix is also not compact and densified as in the case that the matrix contains hydrated products in abundance, and

of the sample that are exposed to 300°C, the reason behind thus, the residual compressive strength of the specimen gave a

positive value.

this could be high temperature exposure that had loosen

the internal microstructure of the specimen. Thus, there is a Similarly, the EDS analysis of the same mortar samples that are

reduction in compressive strength of the mix at this temperature. exposed to 600°C is presented in figure 6. In figure 6, spot 1

Mortar matrix

Steel fibre

Spot-1 Spot-2

Det: Octane Elect Super Det: Octane Elect Super

Figure 5: EDX analysis of B-S-P S at 300°C

THE INDIAN CONCRETE JOURNAL | MARCH 2022 41