Page 8 - February-2022

P. 8

TECHNICAL PAPER

0.7 100

90

ensity (-) 0.65 80

70

60

d Cumulative percent passing (%) 50

Packing 0.6 30

40

20

0.55 10 0 0.1 1 10 100 1000 10000

0 0.2 0.4 0.6 0.8 1

Particle size (µm)

Vol. % CEM II A-L 52.5 N MAAC ideal Mix 1-1 Mix 1-2

KB 2 KB 5 KB 10 KB 45 CEM II A-L 52.5 N grading curve Mix 1-3 Mix 1-5

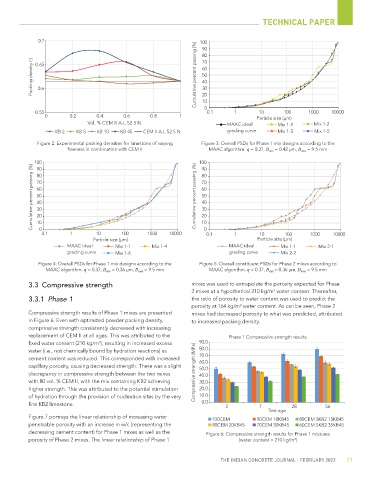

Figure 2: Experimental packing densities for limestone of varying Figure 3: Overall PSDs for Phase 1 mix designs according to the

fineness in combination with CEM II 100 MAAC algorithm. q = 0.37, D min = 0.42 µm, D max = 9.5 mm

Cumulative percent passing (%) 100 Cumulative percent passing (%) 80

90

90

80

70

70

60

60

50

50

40

40

30

30

20

10

10

0

0.1 1 10 100 1000 10000 20 0 0.1 1 10 100 1000 10000

Particle size (µm) Particle size (µm)

MAAC ideal Mix 1-1 Mix 1-4 MAAC ideal Mix 1-1 Mix 2-1

grading curve Mix 1-6 grading curve Mix 2-2

Figure 4: Overall PSDs for Phase 1 mix designs according to the Figure 5: Overall constituent PSDs for Phase 2 mixes according to

MAAC algorithm. q = 0.37, D min = 0.36 µm, D max = 9.5 mm MAAC algorithm. q = 0.37, D min = 0.36 µm, D max = 9.5 mm

3.3 Compressive strength mixes was used to extrapolate the porosity expected for Phase

2 mixes at a hypothetical 210 kg/m water content. Thereafter,

3

3.3.1 Phase 1 the ratio of porosity to water content was used to predict the

porosity at 164 kg/m water content. As can be seen, Phase 2

3

Compressive strength results of Phase 1 mixes are presented mixes had decreased porosity to what was predicted, attributed

in Figure 6. Even with optimized powder packing density, to increased packing density.

compressive strength consistently decreased with increasing

replacement of CEM II at all ages. This was attributed to the Phase 1 Compressive strength results

fixed water content (210 kg/m ), resulting in increased excess 90.0

3

water (i.e., not chemically bound by hydration reactions) as 80.0

cement content was reduced. This corresponded with increased 70.0

capillary porosity, causing decreased strength. There was a slight 60.0

50.0

discrepancy in compressive strength between the two mixes Compressive strength (MPa) 40.0

with 80 vol. % CEM II, with the mix containing KB2 achieving 30.0

higher strength. This was attributed to the potential stimulation 20.0

of hydration through the provision of nucleation sites by the very 10.0

fine KB2 limestone. 0.0

3 7 28 56

Test age

Figure 7 portrays the linear relationship of increasing water

100CEM 90CEM 10KB45 80CEM 5KB2 15KB45

penetrable porosity with an increase in w/c (representing the 80CEM 20KB45 70CEM 30KB45 60CEM 5KB2 35KB45

decreasing cement content) for Phase 1 mixes as well as the Figure 6: Compressive strength results for Phase 1 mixtures

porosity of Phase 2 mixes. The linear relationship of Phase 1 (water content = 210 kg/m )

3

THE INDIAN CONCRETE JOURNAL | FEBRUARY 2022 11