Page 5 - Open-Access-February-2020

P. 5

TECHNICAL PAPER

indicators and the proper application and interpretation of 2.2 scope

these metrics. Fernandez-Sanchez & Rodriguez-Lopez [12] also

argue that the many ISO standards that have been developed 2.2.1 Mix Designs

with respect to sustainability indicators serve as a framework, Six mix designs are shown in Table 1. The concrete mix

rather than a methodology for creating and selecting indicators. designs use general use (GU) cement, general use limestone

Therefore, there is a need for straightforward methodologies (GUL) cement (contains ~12% limestone), as well as three

for developing sustainability or green indicators, and that these Supplementary Cementitious Materials (SCMs) (ground

must be clearly associated with the context of a specific project granulated blast furnace slag (SL), fly ash (FA), and silica fume

and stakeholder priorities. (SF)). All of the mix designs are practical mixes used in projects

at Ontario, Canada. The 100GU mix design is the base case

In this paper, the concepts of LCA are applied to develop scenario. Similar contents of cementitious materials in a range

a methodology for calculating Environmental Disturbance of 351 – 354 were used in the mixes 1, 2, 4 and 5 to compare the

Indicators (EDIs) for six concrete mix designs. A methodology for effect of GU and GUL cement on concrete properties.

combining the LCA outputs with the functional performance of

the concrete products, as measured by the measured hardened 2.2.2 System Boundary and Assumptions

properties (strength and durability) is proposed. The result is

the development of EDIs, which allow for the comparison of Figure 1 presents the cradle-to-grave system boundary for

diverse concrete constituents on the basis of both, life cycle conventional (base case mix design) concrete (indicated in

environmental impact and functional performance. this paper as 100GU) which includes GU cement, fine and

coarse aggregate, and water. The processes for conventional

concrete represent the baseline system boundary. Each process

2. LCA – GOAL AND sCOPe DeFINItION is comprised of input and output data such as energy use,

raw material use, and emissions to air, land, and water, that

2.1. Goal

correspond to the activities including electricity grid mix, water

EDIs are proposed as metrics for the assessment of both treatment, aggregate production, cement production, concrete

environmental and functional performance. This paper presents plant operation and end-of-life. Figure 2 indicates the electricity

a methodology for LCA and the development of EDIs for grid mix composition, which includes nuclear, hydroelectric,

concrete materials. The goal of this LCA is to critically compare natural gas, and alternative means of energy production and

alternative concrete constituents based on their environmental is modelled based on the mix in Ontario in 2014. The water

and functional performance. treatment process is the extraction and processing of water.

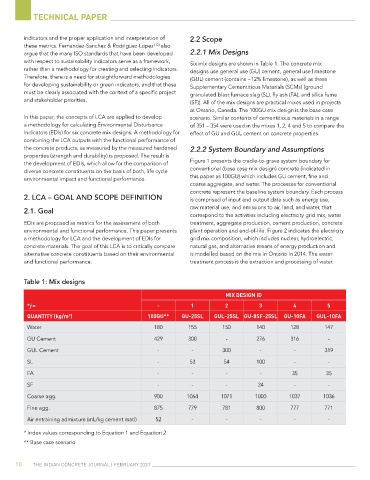

table 1: Mix designs

MIX DESIGN ID

*j = - 1 2 3 4 5

QuANTITY (kg/m ) 100Gu** Gu-25Sl Gul-25Sl Gu-8SF-25Sl Gu-10FA Gul-10FA

3

Water 180 155 150 140 128 147

GU Cement 429 300 - 276 316 -

GUL Cement - - 300 - - 319

SL - 53 54 100 - -

FA - - - - 35 35

SF - - - 24 - -

Coarse agg. 900 1064 1071 1000 1037 1036

Fine agg. 875 779 781 800 777 771

Air entraining admixture (mL/kg cement matl) 52 - - - - -

* Index values corresponding to Equation 1 and Equation 2

** Base case scenario

10 The IndIan ConCreTe Journal | FeBruarY 2020